Services

We are a company specialized 100% in the automotive sector.

Materials Inspection through EDDY

We dedicate ourselves to develop the application of the Eddy Currents technique where we adjust to the geometry of the inspected component as there is a wide variety of coils.

Applications of the eddy currents in Non-Destructive Testing

Measure or identify the conditions or properties such as

• The condition of the induction hardening (Effective Depth of the Layer).

• Superficial hardness as well as hardening of the nucleus.

• Steel mix.

• In some cases, the physical dimensions of the materials.

• Size of the grain.

• Etc.

Magnetic Particles Inspection

We dedicate ourselves, mainly, to the development and implementation of the Magnetic Particles technique, directly from its component; in addition, to carry out the inspection with our highly qualified personnel who have extensive experience in automotive parts.

Industrial Ultrasonic Inspection

The ultrasonic method uses instruments that transmit waves with certain intervals of frequency, and which are applied to detect defects like pores or cracks. Technically, it is called Structural Health Monitoring of the materials.

Our objective is the development and implementation of the ultrasonic technique, directly from its component; in addition, to carry out the inspection with our highly qualified personnel who have extensive experience in automotive parts.

PENETRANT LIQUIDS

The liquids penetrant technique allows us to monitor the defects in the components’ surface during the service inspections and the manufacturing processes where flaws and defects which are not noticeable may be detected by visual inspection. It helps to detect the superficial discontinuities in any non-porous material. The liquids penetrant testing is frequently applied in the manufacturing processes and in the service inspection.

IMAT NDT utilizes penetrant liquids from prestigious manufacturers who guarantee that their products comply with the requirements set by the standards. Our technicians are trained to satisfy the needs of your clients and to solve the difficulties that may arise.

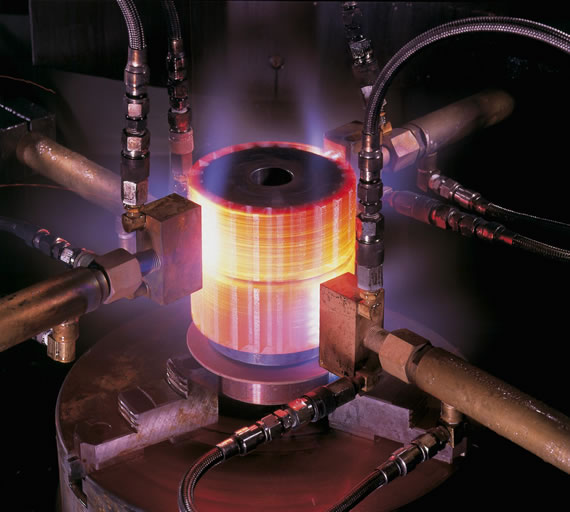

Induction Heat Treating

• Induction Heat Treating Courses.

• Counseling for the induction tempering processes.

Consumables sale for NDT testing.

• Fluorescent and visible Magnetic particles and penetrant liquids.

Sale of accessories and ultrasonic detectors for failures